The SOCO TF Tube End Former Series is widely used in numerous end forming applications and industries, such as automotive exhausts, furniture, and air conditioning, among others. These machines are different than conventional end formers, due to their low setup, high flexibility, superior precision, and compact design.

These machines go up to 82 mm in size and incorporate hydraulic operation and touch screen control. They may be fitted with 1 or 2 operating stations to process operations on tube ends and are suitable for both straight and bent tubular parts.

IO Types

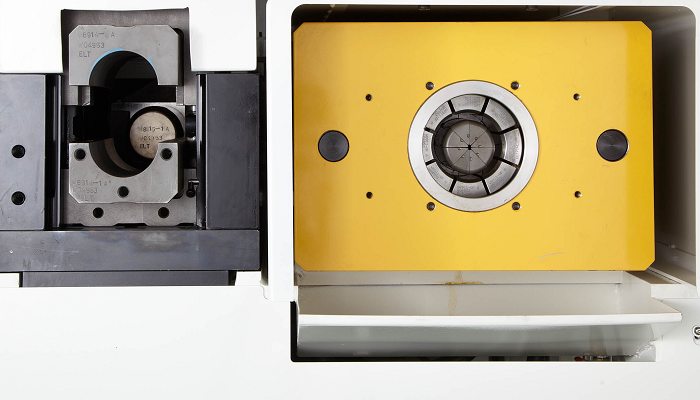

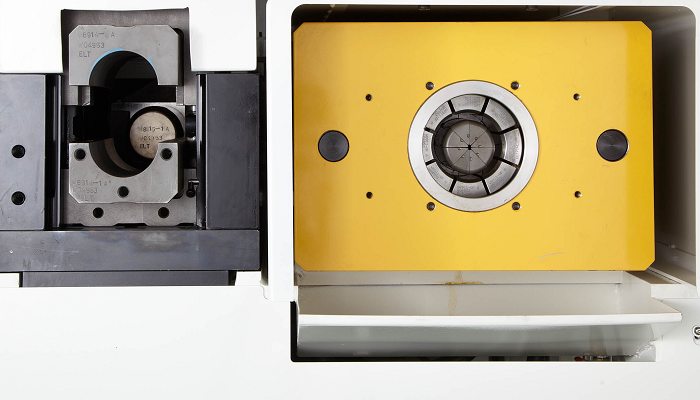

The IO type is used for precision sizing of tubes and uses a combination of expanding segments and reducing jaws for accurate control of the inside and outside diameters. These can be sequenced in any order for improved accuracy and reduced ovality. The I/O also incorporates a touch screen control for quick setup.

The IO type is used for the highest accuracy and control of the inside or outside diameters (ID/OD) of the tube. Unlike tooling systems used in the C and E type, the I/O type tooling is comprised of a set of inside expanding fingers and outside reducing jaws. These can be sequenced in any order to give improved sizing accuracy and minimal ovality.

These machines go up to 82 mm in size and incorporate hydraulic operation and touch screen control. They may be fitted with 1 or 2 operating stations to process operations on tube ends and are suitable for both straight and bent tubular parts.

IO Types

The IO type is used for precision sizing of tubes and uses a combination of expanding segments and reducing jaws for accurate control of the inside and outside diameters. These can be sequenced in any order for improved accuracy and reduced ovality. The I/O also incorporates a touch screen control for quick setup.

The IO type is used for the highest accuracy and control of the inside or outside diameters (ID/OD) of the tube. Unlike tooling systems used in the C and E type, the I/O type tooling is comprised of a set of inside expanding fingers and outside reducing jaws. These can be sequenced in any order to give improved sizing accuracy and minimal ovality.

up to 82 mm, 1 or 2 operating stations